How to Ship Pharmaceutical Products Safely

When shipping pharmaceuticals, you need to consider many factors to ensure they’re transported safely. Changes in temperature, climates, and humidity can affect the chemical formula of the drugs and, in some cases, can also deteriorate their shape and texture.

As a result, this can significantly affect the efficacy of medicines and other pharmaceutical products.

Here are some ways to ensure the safe shipping of pharmaceuticals.

Maintaining temperatures

Controlling the temperature is crucial when moving pharmaceuticals from one place to another. Most pharmaceutical products are shipped at 55 to 77 F to ensure stability. Refrigerated trucks and containers are commonly used to maintain the optimal temperature levels throughout the shipment.

If the environment is too hot, the pharmaceuticals may lose their composition, and their formula might be affected. Not only may this affect the health of the patient, but it can also lead to legal consequences for the pharmaceutical company.

Packaging pharmaceuticals

Another important aspect of pharmaceuticals’ shipping is their packaging. Pharmaceutical products are usually shipped in insulated containers that protect the products from fluctuating temperatures, humidity, damaging sunlight, and more.

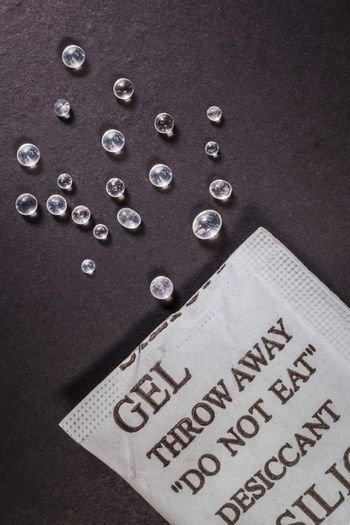

Some shippers also use desiccant pallets to ensure optimum humidity for the products because a rise in moisture levels inside a container can soften tablets and deform their shape and texture.

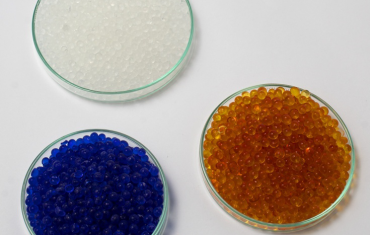

Some common pharmaceutical desiccants include:

Silica gel: it is manufactured from sulfuric acid and sodium silicate. Since it is non-hazardous, it can be placed with drugs as an absorbent. Silica gel is highly porous and can absorb more than 40% of its weight in water.

Montmorillonite clay: This is a natural adsorbent. This clay can be regenerated for repeated use at low temperatures without substantial swelling. Clay is affordable and very effective in normal temperatures to protect pharmaceuticals.

Carbon: Although it is not technically a desiccant., carbon is normally packaged with pharmaceutical products to remove the odor that may result from increased humidity in the environment. Carbon can also be mixed with desiccants as an odor remover.

Molecular sieve: This desiccant contains a network of empty cavities and uniform pores, allowing them to absorb moisture efficiently. They are one of the most expensive and aggressive types of desiccants used in pharmaceuticals.

Buy Pharmaceutical desiccants at Sorbead India

Sorbead India offers high-quality pharmaceutical desiccants, including silica gel, molecular sieve desiccant, montmorillonite clay, carbon, pharmaceutical coils, and more.

We also deal in desiccant tablets, pillow packs, desiccant canisters, and container desiccants. Contact us today to learn more about our products.