Application of Desiccants in the Pharmaceutical Industry

Desiccants are substances that absorb moisture from the air. These substances have important industrial uses, and their application in the pharmaceutical industry is particularly significant.

Desiccants for pharmaceuticals maintain an optimal environment for storing drugs and other materials, which can make a huge difference in product quality.

Moisture Control

Desiccants are commonly used to control the level of humidity in pharmaceutical packaging, where they help to prevent the growth of mold and other microorganisms.

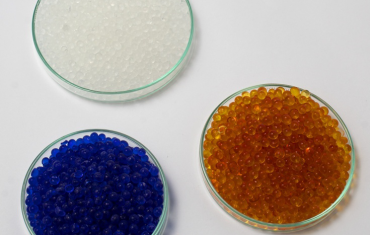

Several types of desiccants are available on the market, including silica gel, calcium sulfate, and clay. Each type has its advantages and disadvantages, so choosing the right one for your particular needs is important.

Silica Gel

The most popular desiccant type due to its high moisture absorption capacity and low price. However, it is not as effective at adsorbing moisture from the air as other types of desiccants.

Calcium Sulfate

It is more expensive than silica gel, but it is more effective at adsorbing moisture from the air. It is also non-toxic and safe to handle, making it a good choice for pharmaceutical applications.

Clay

The least expensive desiccant type, but it is less effective at absorbing moisture than other types. However, it is safe to handle and does not release toxic fumes, making it a good choice for pharmaceutical packaging applications.

Keeping Medication Dry and Protected

Pharmaceuticals are especially susceptible to moisture damage, as even a small amount of moisture can degrade the quality of the medication. Medications must be kept dry to maintain their potency and safety.

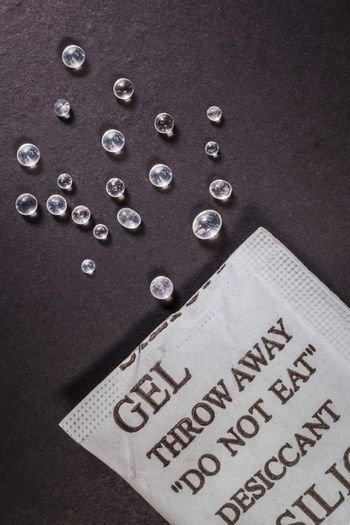

Desiccants can help to keep medications dry and protected from moisture damage. They can be added to packaging or placed inside containers with medications. Desiccants will absorb any moisture present, keeping the medication dry.

If you are using medication that needs to be kept dry, consider using desiccants to protect it from moisture damage.

Preventing Medication from Clumping

Desiccants prevent the medication from clumping. When medication is exposed to high humidity, the moisture in the air can cause it to clump together.

This can make the medication less effective or even dangerous. Desiccants can help to prevent this by absorbing the moisture from the air, keeping the medication dry and effective.

Conclusion

Desiccants play a vital role in the pharmaceutical industry by providing an effective means of controlling moisture levels. In addition to their ability to absorb moisture, desiccants are non-toxic and can be used safely around food and medicines.

Furthermore, they provide a cost-effective solution that is easy to implement in any production environment. The use of desiccants has been key in ensuring the quality, safety, and efficacy of many medications on the market today and will continue to be an important factor within this ever-changing industry.

Sorbead India also specializes in providing desiccants for diagnostic kits, so your company can ensure the preservation of the integrity of these products as well. They are on the task of providing your pharmaceutical company with the perfect desiccants!