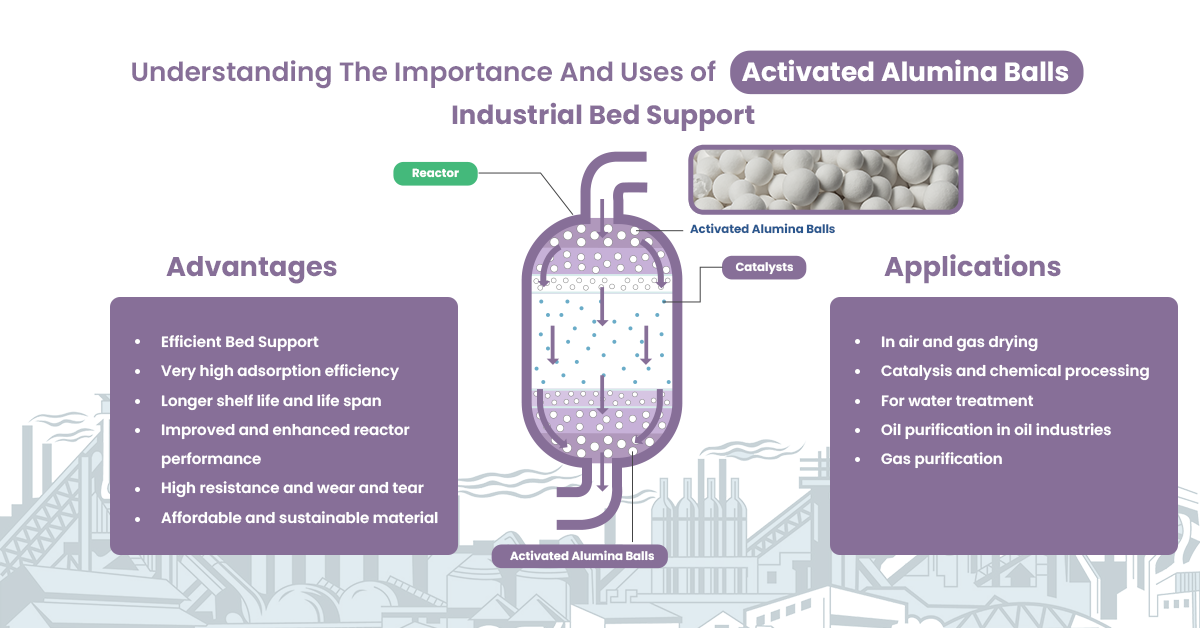

Uses Of Activated Alumina Balls For Industrial Bed Support

Activated alumina balls are a highly versatile, widely used, and effective material used in a wide range of industrial applications. They have a very high surface area, porosity, mechanical and chemical stability, and inert nature, making activated alumina balls ideal for use as bed support in various industrial processes. They are an essential element of many industrial filter systems because they offer better filtering efficacy, heat transfer performance, and wear and tear resistance due to their numerous useful adsorbent characteristics.

Activated alumina balls for industrial bed support are used as the active catalyst support material in the reactor and tower packing. They are mainly used and implemented to provide low strength support and protection for the active catalyst and to increase the distribution point for gas or liquid. Their unique properties help support and protect sensitive catalytic converters, improve flow distribution, and can also act as efficient filters, that result in improved process performance, product quality, and longer shelf life of equipment.

The role of Activated alumina balls in industrial bed support

Activated alumina balls are used in various industrial processes as bed support due to their unique characteristics and properties. Alumina balls are formed by processing aluminum hydroxide into spherical-shaped particles and then heating/sintering to form activated alumina balls at high temperatures.

These highly adsorbent balls have a high surface area, high porosity, and high chemical stability and are used as catalysts, catalytic converters, desiccants in many applications, adsorbents, gas purifiers, also to remove fluoride from drinking water, eliminate color and odor from industrial sewage, etc.

Alumina balls also serve as inert bed supporting media in high temperature applications where they can withstand high temperatures and high adsorption pressures. For bed support in various industrial applications, the material needs to have a high adsorption rate, large surface area, high tensile strength, and thermal stability, thus, activated alumina balls have all these characteristics and properties making them an ideal material for bed support in various industries, including petrochemical, textile, oxygen, for lead removal from industrial emissions/effluents, and hydrogen peroxide production.

In water treatment plants, activated alumina balls help in the removal of contaminants, ensuring a cleaner and safer water supply, making it cleaner and safer for consumption. Their ability to adsorb impurities like fluoride and arsenic from water samples improves the water purification process.

Their high thermal stability properties make activated alumina suitable for applications with high temperatures, making it a versatile material. Activated aluminum balls can be efficiently used as reliable bed support materials and agents, to increase the efficiency, reliability, and durability of many different and critical industrial processes.

Advantages of using activated alumina balls for bed support

Efficient Bed Support

Because activated alumina balls have a large surface area and a high porosity level, they can effectively offer high bed support to various catalysts. This high bed support improves heavy hydrocarbon conversion into lighter, higher value products in catalytic conversion processes and provides a stable, high performance, and highly versatile material for the processes and applications.

Very high adsorption efficiency

Activated alumina balls have very high adsorbency powers and with a large surface area, they can adsorb and trap a lot of contamination, impurities, and other unrelated elements during the purification process and other industrial applications, improving the overall performance and quality of the processes that they support.

Longer shelf life and life span

When compared to other adsorbent materials, activated alumina balls have a very high shelf life, high durability, and resistance to wear and tear making them outlast other bed support materials. This durability results in lower maintenance costs and fewer replacement cycles, resulting in economies of scale for industries over time.

Improved and enhanced reactor performance

The unique properties of Activated alumina balls like the smooth texture and consistent size help in distributing reactants and catalysts uniformly across the bed, and in turn lowering the reactor’s internal pressure drop. The reactor performance is enhanced by using these aluminum balls, there are higher energy savings, and there are better and improved flow dynamics.

High resistance and wear and tear

Activated alumina balls have very high resistance to high temperatures, pressures, wear and tear, high speeds, acids, and corrosive conditions that are common in the hydrocarbon processing industry. Active alumina balls provide long-term protection for catalyst beds and industrial processes.

Affordable and sustainable material

Activated alumina balls are a very cost-effective adsorbent solution for industrial bed support applications. When compared to its alternatives, activated alumina balls are a very budget-friendly option without compromising on quality or performance for so many various industrial applications. They are also a highly sustainable material and can be regenerated to be used multiple times, thus making it an eco-friendly material.

Key applications of activated alumina balls in industrial bed support

In air and gas drying: Activated alumina balls are widely used in the drying of air, gases, and liquids in petrochemical, textiles, and pharmaceutical industries as they have a high surface area and a uniform pore distribution, which allows them to efficiently remove moisture, making them excellent desiccants for low dew point applications.

Catalysis and chemical processing: In the pharmaceutical and chemical industries, activated alumina balls are widely used as catalysts for a variety of chemical reactions, such as the synthesis of steroids and APIs. The catalytic properties of alumina balls play an important role in increasing drug efficacy and bioavailability.

For water treatment: Since activated alumina balls are great adsorbents they can efficiently remove impurities such as arsenic and fluoride from the drinking water. Alumina balls have a high affinity to water molecules and other contaminants, which makes them an effective material for water purification in areas with a high fluoride content.

Oil purification in oil industries: They are used to purify and condition insulating oils or industrial oils. Alumina balls help to eliminate impurities, acids, and impurities from oils, improving the durability and performance of machinery in a variety of industrial applications.

Gas purification: Activated alumina balls are used in gas purification in industries like oil refining to remove various contaminants and impurities such as sulfur compounds from the gas. Alumina balls are chemically stable and resist abrasion, making them an effective adsorbent for the gas purification process.

We are the leading and global manufacturers and suppliers of Activated alumina balls for industrial bed support and provide premium quality desiccants, adsorbents, and other moisture adsorbing solutions for use across numerous different industries and applications.