How to Regenerate Molecular Sieve/Zeolite?

Zeolites or molecular sieves are widely used in various industries and across applications including but not limited to water treatment, pharmaceuticals, and manufacturing. They are a highly efficient material in removing water vapor from gas streams and other processes or subprocesses, reducing energy consumption and emissions effectively.

The material has a crystalline structure, and is highly selective in its absorption and trapping of water molecules, protecting the quality of sensitive pharmaceuticals and industrial processes as they can effectively adsorb water molecules in pharma pollutants in air filters.

Molecular sieves or the Zeolite material is also regenerative in nature, this makes them a sustainable and eco-friendly option as this means they can be reused and regenerated multiple times. This reduces the overall carbon footprint on the environment, as they do not end up in landfills repeatedly when compared to other non-sustainable materials.

But, you must be wondering, how to regenerate molecular sieve/Zeolite? This can be achieved in easy and simple ways, which we will see in detail in this blog post. Since the material is easy to regenerate the process is pretty simple and can be done multiple times to obtain high efficiency in adsorbency.

How to regenerate molecular sieve/Zeolite materials?

The molecular sieve structure is highly porous and can adsorb large amounts of moisture, vapor, and humidity. Once saturated, it needs to be regenerated to make it effective again, and thus there are many ways that can help us with the regeneration of the molecular sieves and Zeolite materials.

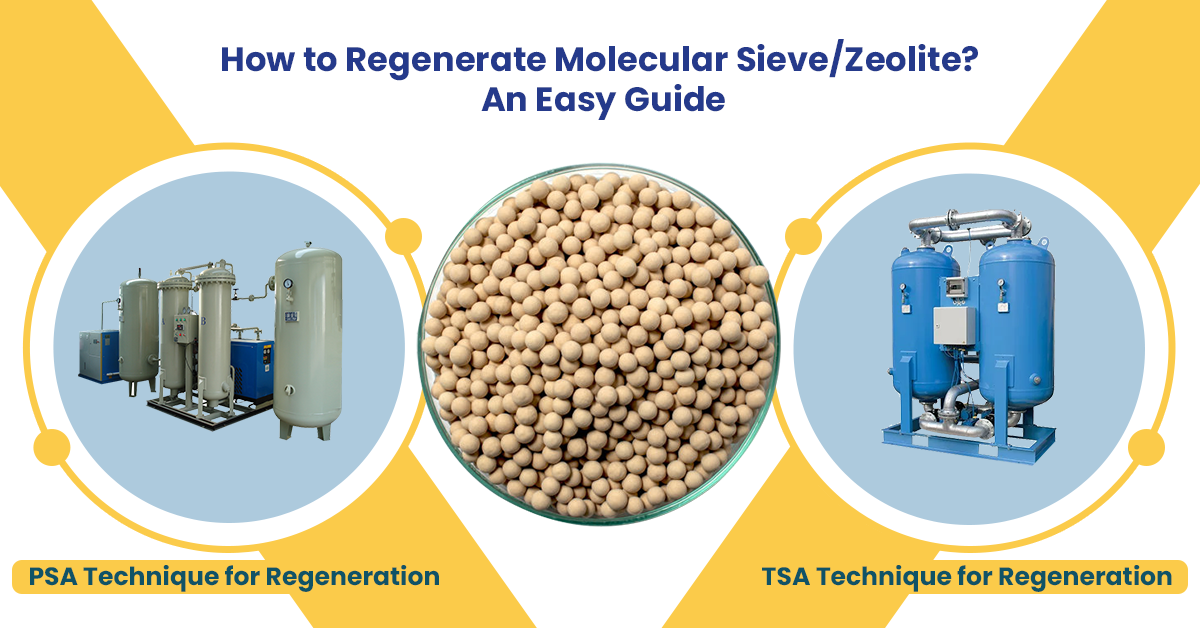

The two main techniques that can be used for the regeneration of Zeolites are Pressure Swing Adsorption and Temperature Swing Adsorption techniques. Both techniques can be used to obtain high quality Zeolite materials when they are saturated with excess moisture and humidity.

Pressure Swing Adsorption technique for regeneration

In this well-known technique, the regenerative process uses different variations in pressure to rid the molecular sieve structure of the adsorbed moisture or water vapor and make it reusable for the next water-absorbing cycle. The molecular sieve selectively adsorbs moisture at high pressure in the adsorption phase. And in the desorption phase, the pressure is then reduced, prompting the material to release the adsorbed water/vapor/humidity easily. This phase is crucial for regenerating the sieve.

The PSA technique for regeneration is highly efficient for continuous drying processes in various industries and is widely used in large-scale applications where a constant supply of dry air or gas is essential. The process of continuous regeneration ensures a consistent supply of dry environment during the use of molecular sieves and Zeolites, and it is highly energy-efficient and suitable for applications with high moisture content.

To regenerate the sieves or Zeolite material, you can increase the temperature and decrease the pressure, or add a new pure gas that will provide enough temperature and pressure to heat the molecular sieve up to 200-300 degrees Celsius for several hours.

Thermal Swing Adsorption technique for regeneration

In this technique, heat is used to regenerate the material of the molecular sieve, to rid it of the moisture it has adsorbed. By exposing the material to proper levels of heat, the moisture trapped in the material is evaporated effectively. It involves using temperature variations to regenerate the Zeolites, and the process uses the desorption of the sieve to evaporate and remove the trapped moisture.

During the heating phase, the saturated molecular sieve is subjected and exposed to high temperatures and here the absorbed water molecules are desorbed and released into the air. And in the cooling phase, once the sieve releases its trapped or adsorbed moisture, it’s time to cool down the material, as cooling the sieve prepares it for the next step in its moisture-absorbing process.

It is a very simple and effective method, that can be applied to a wide range of molecular sieve types. The TSA technique works well for molecular sieves that have a high affinity for water molecules so that they are effectively adsorbed by the material and is ideal for applications where intermediate or batch drying is possible in the application.

The regeneration process for the Zeolite material is necessary for maintaining the adsorptive power of the material, and it allows for the reuse of molecular sieves multiple times without losing their efficiency, making it a cost-effective and environmentally sustainable material for use in numerous important industrial applications.

Make sure to always follow safety protocols when handling hot zeolites and potentially hazardous regeneration chemicals. Also, keep a close check when regenerating the material to avoid exposing them to very high temperatures or longer periods of time.

List the benefits of using an effective regeneration technique for molecular sieves

– Regular regeneration of the molecular sieves material can greatly help maintain their structural integrity, and prevent premature wear and tear. By removing accumulated moisture and contaminants, the material can be used for a longer shelf life and high efficiency.

– The adsorption capacity of the Zeolite material is largely increased when the saturated material is effectively regenerated using any technique. This happens when clogged sieves can slow down the processes, and affect the quality and efficiency of the overall process.

– By regenerating the material and reusing it multiple times, you are improving its resource utilization without compromising its performance. The regeneration process prevents them from ending up in landfills, which has a positive effect on the environment. The process continues to operate efficiently, and the environment benefits from less waste and resource use.

– The regeneration process can be done at a relatively low cost, making it an affordable option for industrial companies and businesses that use molecular sieves for numerous applications, techniques, and uses, as proper regeneration of the Zeolites can save up to 70% of the cost compared to buying new sieves for different processes. It is important to plan, properly design, and operate the regeneration phase of molecular sieves to ensure that the molecular sieves are not damaged during the regeneration process and retain their structure, function, and power throughout their shelf life. We are industry leaders and manufacturers of high quality molecular sieve / Zeolite that can be used for optimal moisture adsorption.