How to Prevent Damage to Equipment from Corrosion?

Corrosion is a natural process but a common struggle for manufacturers since they must protect their equipment.

There’s no denying that silica gel and other desiccants can help prevent corrosion, but we’ve compiled some additional tips for you to tackle this issue.

Use Non-Corrosive Metals

. Instead of using various materials and tips to control corrosion, eliminate the chances by using non-corrosive metals to manufacture them. Through this, you can easily dodge corrosion stress, and your equipment can last longer too.

Some common examples of metals that don’t corrode are aluminum, stainless steel, brass, bronze, galvanized steel, etc.

Opt for Cathodic Prevention

If you’re looking for helpful tips to prevent your equipment from decaying, cathodic protection can help. Cathodic protection is a common technique used to manage the corrosion of metal surfaces. This is done by making the metal surface an electrochemical cell’s cathodic side.

The easiest way to use cathodic protection is by attaching the metal requiring protection to another metal. Remember, the latter needs to be an easily corrosive method so it can serve as the electrochemical cell’s anode.

Although cathodic protection is primarily used to safeguard steel structures submerged in water or buried in soil, it can also be used for any metallic structure near a bulk electrolyte. Some most common applications of cathodic protection are:

- Fuel and water pipelines

- Ships and boats

- Storage tanks

- Oil well casings

- Offshore oil platforms

Consider Coatings to Prevent Corrosion

Cathodic protection might not be a good approach for all equipment. However, you could opt for another method—coatings. By coating your surfaces, you can reduce the risks of corrosion. For instance, you can apply inorganic paint to surfaces likely to rust.

The paint will protect the metals from external factors causing them to decay. Although safer to apply, it can be used just like metal plating. This coating type has an anti-corrosive effect by combining silicon, aluminum, and zinc.

Use Desiccants

The leading cause of corrosion is moisture. When a surface is exposed to constant humid air, the moisture can cause it to rust. An effective way to prevent corrosion would be by ensuring your equipment is moisture free. If you’re wondering how, the solution is desiccants.

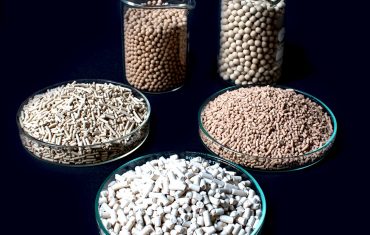

Desiccants are a cost-effective substance for eliminating excess moisture, eventually preventing rust. Some highly effective desiccants are silica gel and molecular sieves since they’re absorbent and can offer noticeable results.

Besides silica gel and molecular sieves, you can use other desiccants and oxygen absorbers. So, make sure your equipment is packed and sealed with desiccants.

Are you looking for quality silica gel moisture absorber and other desiccants? Look no further than Sorbead India to buy desiccants online.

At Sorbead India, we take pride in being a leading desiccants and adsorbents manufacturer, including top-tier Chromatography media, silica gel, activated alumina, molecular sieves, pharmaceutical coils, and more.

Get in touch with us today to purchase and explore our products.