How do Desiccants Help Prevent Erosion and Rust?

In most of the auto and other manufacturing industries, smaller parts are usually designed at one place, manufactured and packaged at another location, and then shipped for storage or assembly to a different location. Sometimes the parts need to be shipped across the countries, hundreds of miles apart, requiring large shipments to be made across oceans or continents. This may lead to them undergoing permanent damage such as rust and erosion.

How and Why Manufacturing Parts Get Rusty

Long-haul container shipments are exposed to huge oscillations in the humidity and temperature of the air that surrounds the manufacturing parts. An immediate fall of 9 to 11° C can lead to residual moisture in the packaging materials, ambient air, and even wooden floors of the container. This may result in condensation inside the container and lead to, what is famously known as, “container rain”.

Parts that are sensitive to moisture such as ferrous metals are very vulnerable because a humidity level of forty percent or more can result in rust. Repeated rise and fall in the temperature and humidity increase the risk of rust and erosion.

What are Desiccants?

Desiccants are hygroscopic substances, which means, they can absorb water from the surrounding atmosphere. They can absorb around forty percent of their weight in water and maintain a constant relative humidity.

How Can Desiccants Help Prevent Rust and Erosion?

When residual moisture or container rain builds up inside the cargo ships, desiccants help to diffuse or remove the moisture and keep it at the desired level.

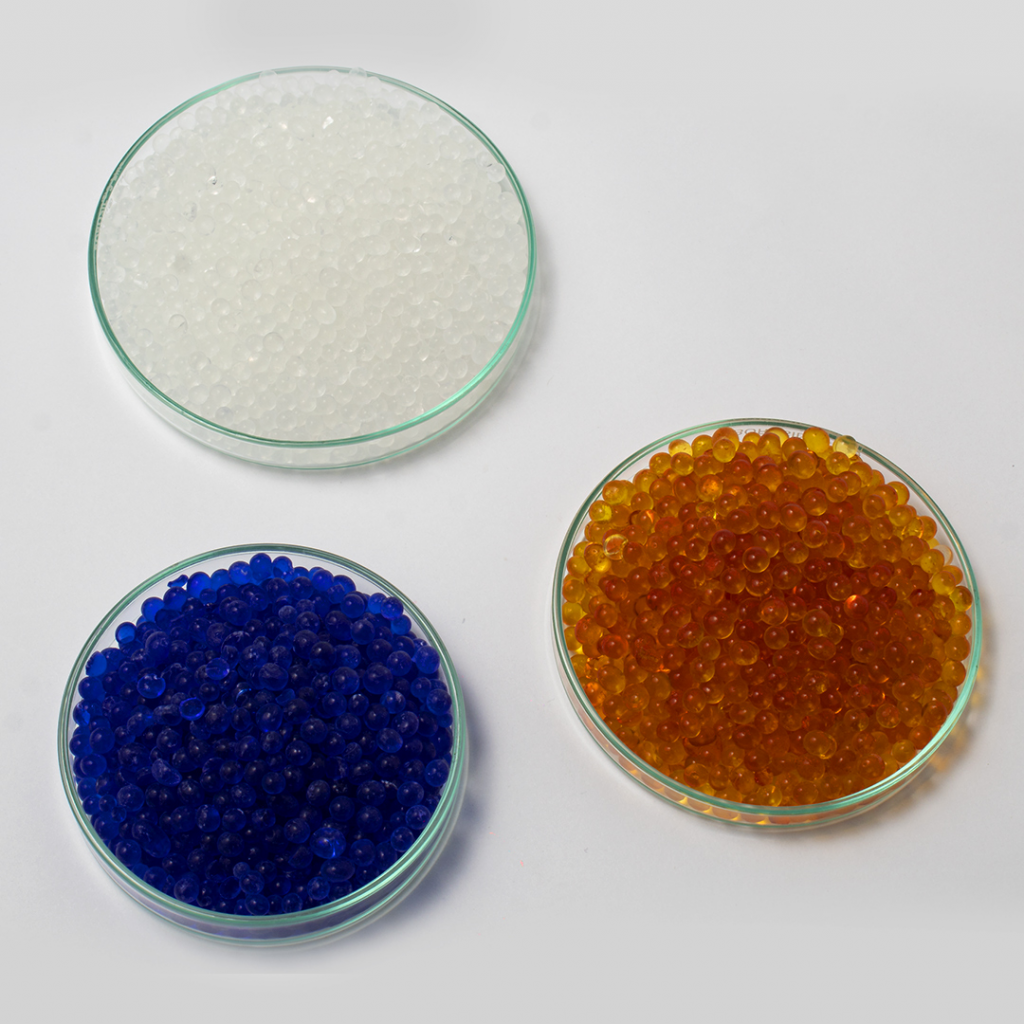

There are a variety of desiccants available in the market today. The desiccant systems help to maintain ideal humidity levels to prevent rust and corrosion of sensitive components.

Desiccant absorbents use silica gel as their main desiccant material. Silica gel is highly effective in absorbing any residual moisture from the air due to its large surface area and highly porous molecular structure.

The molecular structure of silica gel has a large affinity for both water and humid air. It forms a special bond with the bound water molecules. This helps it to remove water from the air without absorbing any other hydrocarbon or polar substance in the surrounding atmosphere. This removes all humidity from the surroundings, keeping them at constant humidity levels, and thereby eliminating rust and corrosion problems.

If you’re looking for desiccants to use to prevent rust and erosion in sensitive manufacturing of auto parts, we’ve got you covered. At Sorbead India, we offer a range of quality desiccants including silica gel desiccant packets, active alumina, moisture-free packaging solutions, silica gel orange crystals, and much more.

Contact us today to learn more about our products!