How do Absorbents and Desiccants Work?

When considering packaging options for your products, you may have come across the terms “moisture control,” “absorbents,” “adsorption,” and “desiccants.”

Absorption refers to the process during which a material chemically integrates into a separate substance.

Adsorption, however, refers to when a substance is being held inside another material using physical bonds. For example, when you spill water on a cotton t-shirt, the water is adsorbed since the fibers hold the water until heat causes it to dry.

Desiccants use the latter method to prevent other materials from being damaged by water. They won’t chemically combine with the moisture they encounter. Instead, they will hold them to prevent the water from damaging the product.

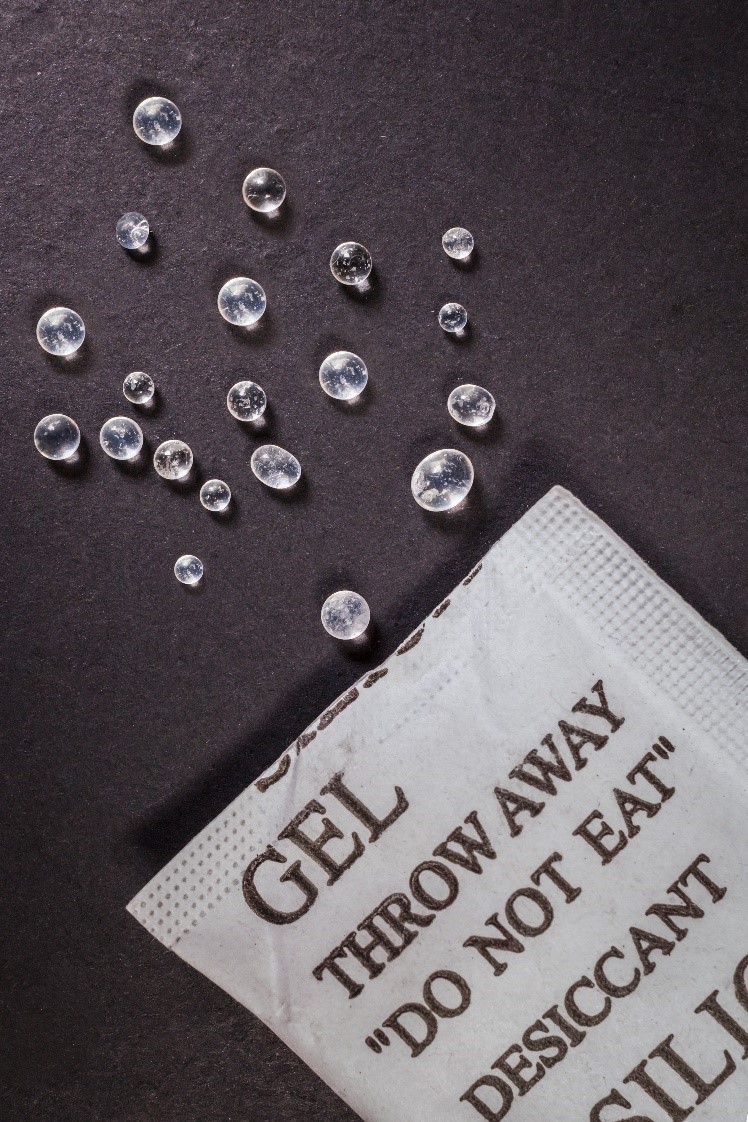

There are many kinds of desiccants available in the market, including molecular sieve, activated carbon, calcium sulfate, and silica gel.

These are all used for various purposes and reasons. Therefore, it’s essential to select the appropriate type of desiccant to suit your intended purpose.

How Do Desiccants Work?

Desiccant products work to adsorb moisture from the air. Porous adsorbents like activated clay, silica gel, or molecular sieves use physical adsorption instead of chemical adsorption to protect the products around them.

Physical adsorption takes the comparatively weak intermolecular forces between the desiccant surface and the moisture. The drying agents work by attracting small layers of moisture molecules from the air to the desiccants’ surface.

Chemical adsorbents like calcium oxide, however, involve chemical bonds. The physical adsorption process is usually exothermic, which means the adsorptive bonds’ strength can be measured relative to the adsorption heat.

The higher the heat level, the stronger the bond will be, and therefore, lesser moisture will be eliminated from the surrounding.

How Does Moisture Damage Products?

The contents of a package can be damaged by the humidity or water trapped inside the container. If that moisture leaks into the container during transit or storage, it can harm the products inside.

Many pharmaceutical formulations and industrial products depend on the moisture conditions of their package to stay usable.

If the package environment is unsterile, any moisture seepage can cause mold, mildew, and fungi to grow inside.

Moreover, plastic and polymer products can swell and become misshapen in high humidity environments since the intermolecular bonds between the polymer chains get broken by water.

With electronics, moisture can cause corrosion and lead to short circuits, causing extensive damage.

Therefore, safety lies in properly using absorbents and desiccants to package your products. Sorbead India is a reputable distributor of desiccants operating in Gujarat, India.

We provide high-quality desiccants and absorbents for all kinds of industrial needs. Visit our website to buy silica gel and other moisture absorbers online.