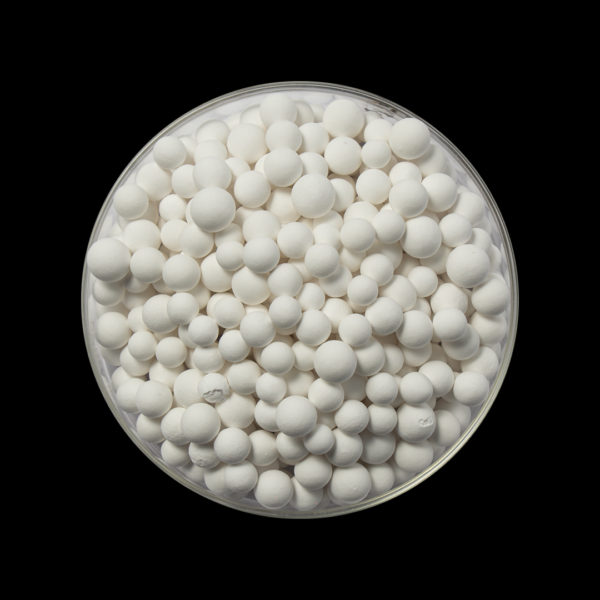

Activated Alumina Balls

Activated Alumina Ball is Aluminium Oxide that is highly porous and exhibits a higher surface area. Activated Alumina Ball widely used in Instrumental Air Drying suitable for Heat Less Air Dryer, Heat Reactivated Dryer, Heat of Compression Air Dryer & Reciprocated Air Dryer. Activated Alumina Ball offers desirable performance in all brands of Air Dryer.

Activated alumina grade SORB-I (AD – 101) having a surface area in the range 345-415 m2/g. because it has the highest water absorption capacity then other adsorbents. Sorbead India supply alumina balls for thermal swing adsorption process, oil filtration, air & gas drying process. We supply alumina balls for HOC, heated and heatless air drying process, as well as alumina for fluoride and arsenic removal. Get effective moisture/water absorption results from the air for a long time with regeneration process.

Advantages :

- High Crushing Strength

- High Adsorption Capacity

- Low Bulk Density

- Low Attrition loss

- Dust-Free Operation

- Longer Service Life

- Technical Parameter

- MSDS

- Applications

| Parameters | Instrument Air Drying Grade | |

| Physical Properties | ||

| Shape | Spherical Beads | Spherical Beads |

| Size In mm | 1/8”

(3.12 mm) 2-5 mm |

1/4′′

(6.25 mm) 5-8 mm |

| Surface Area m2/gm | 350-415 | 350-415 |

| Bulk Density Kg/m3 | 700-800 | 700-800 |

| Pore Volume cc/gm | 0.40-0.50 | 0.40-0.50 |

| Attrition Loss % | < 0.2 | < 0.2 |

| Adsorption Capacity @ 60% RH & 25° C % | ≥ 20 | ≥ 20 |

| Crushing Strength N | 80-120 | 120-240 |

| Loss On Drying % | < 1.5 | < 1.5 |

| LOI (300° C-1000° C) % | 6-8 | 6-8 |

| Chemical Properties | ||

| Al2O3 By Difference Min | 92 .7% | 92.7% |

Remarks : All the parameters to be customized as per the client requirement

Enter your email to receive the MSDS

- For Instrumental Air Drying in Air Drying System in POY Yarn & Staple Fibre Yarn Industries, Polyester Chips Industry

- Compressed Air Drying Systems

- For Sulphur Recovery Plant

- TSA / PSA Oxygen Plant

- Transformer Oil, Lubricating Oil, and Refrigerant Purification

- Peroxide Removal from Organic Solvent Tetrahydrofuran

- Pneumatic Air Breaking Dryer

- HVAC Filter Dryer System