How Does Activated Alumina Ensure Enhanced Fluoride Removal

The concentration of fluoride in drinking water has become a global issue in the last few years. In small concentrations (1–1.5 mg·L−1), fluoride strengthens the enamel and enhances bone formation. However, higher levels (>1.5 mg·L−1) have been linked to dental and skeletal fluorosis.

More than 200 million people across the globe drink fluoridated water, and fluoride-related diseases are found in over 70 million people. Prevalent symptoms include stiffness and pain in the joints.

The good news is there is an efficient way to treat water with excess fluoride concentration. The adsorption technique uses activated alumina to get rid of fluoride concentrations.

Here’s a quick overview of why we need to treat fluoridated water and how activated alumina works.

Why do we need to treat fluoridated water?

As urbanization and industrialization continue to burgeon, the quest for sources of clean drinking water is more important than ever. At the same time, many sources of water are becoming increasingly contaminated and thus, unfit for human consumption.

Among other contaminants, fluoride has become a high priority because of its carcinogenic properties. Fluoride, once ingested, can accumulate in the body, leading to several health problems. This is why water needs to be treated before consumption.

Perhaps another reason for the growing concern is that freshwater sources are also showing high fluoride concentrations. While previously, it was only groundwater sources that did, mineral and rock formations have changed the chemical composition of freshwater too.

Activated alumina for water treatment

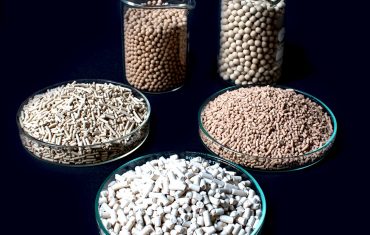

Activated alumina is considered to be the best technology for fluoride removal in aqueous sources. Aluminum oxide has a high surface area and a micro-porous composition that allows it to absorb water with ease.

Additionally, the activated alumina can be regenerated, which makes it cost-efficient too. During the regeneration process, the alumina balls are dipped in a dilute caustic solution to strip the adsorbent fluoride. The next step involves rinsing and reconditioning, after which the alumina can be used again.

Image Filename: activated-alumina-balls

Image Alt Text: activated alumina balls in a lab setting

Choose reliable activated alumina suppliers

Sorbead India is a leading provider of moisture-free packaging solutions to a variety of industries. Our activated alumina products are suitable for several applications including water treatment and air drying.

For more information about the company or to learn more about our products, send us an inquiry or call +91-756-768-8877.