Here’s Everything You Should Know About Activated Alumina

Activated alumina is simply aluminum oxide in a solid and porous form, often known as alumina, or by its chemical composition, Al2O3. Interestingly, bright-colored gemstones like ruby and sapphire are composed primarily of aluminum oxide, with their bright colors coming from impurities in the mineral.

The ‘tunneled’ structure of Activated Alumina makes it useful for many use cases; for example, drying gases, which is a necessary step for transporting volatile gases. Famous for its adsorption qualities, activated alumina has numerous other uses as well.

Let’s look at some of them a little more closely.

What Is Activated Alumina Used For

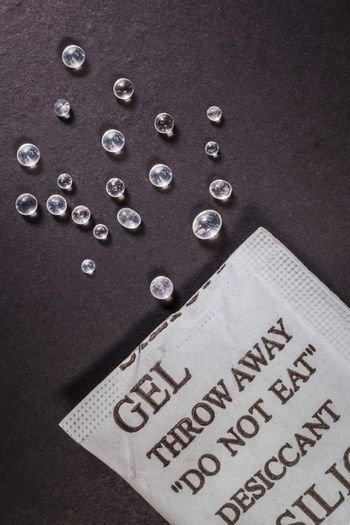

Desiccation or absorption of water is an essential use case of Activated Alumina. Other uses include helping clean up toxic materials or waste from industries and factories, including water runoff, to reduce the chances of contamination in the environment.

It is also popular for cleaning rainwater runoff—which is known for picking up toxic elements like soluble metal from various industrial activities in industrial zones and areas.

Activated alumina is also helpful when it comes to cleaning up sites that have suffered toxic spills and is an efficient way to encourage a clean environment. Its chemical composition allows it to bind with toxic substances, preventing them from leaking back into the environment.

A feature that sets activated alumina apart from other adsorbents is its stable chemical structure. This means that even though the mineral can bond with impurities, it won’t change its own composition, which makes it perfect for use in the purification processes in industries and even municipal water treatment.

How Is It Different From A Molecular Sieve?

Even though molecular sieves perform the same function—adsorbing moisture—the two differ in many ways. The feature that sets molecular sieves apart is that their pore-size can be adjusted by ion exchange. This allows molecular sieves to separate molecules based just on size—unlike activated alumina.

Another difference is that activated alumina is hydrophilic and poses a much higher affinity for water, which makes it an easy choice in gas drying processes. Activated alumina also has a high crush strength, allowing it to maintain its structure and properties under higher pressures during industrial processes.

Are you on the look-out for premium-quality Activated Alumina in bulk quantity for industrial processes or water treatment? Feel free to reach out to our team today.

At Sorbead India, we manufacture and supply the highest quality of activated alumina, oxygen absorber packets and USDMF desiccants our clients at market-competitive rates throughout the country.

If you have any questions or queries regarding our products or services, give us a call at +91-756-768-8877.