The Importance of Desiccant Canisters in the Pharmaceutical Industry

As is common knowledge, exposure to environmental factors, such as humidity and moisture, can nutraceutical and pharmaceutical products to degrade, causing them to lose their efficacy and stability over time. In order to effectively protect pharmaceutical products from any kind of damage, manufacturers require an effective dehydrating solution to keep them preserved. This is where desiccant canisters come in.

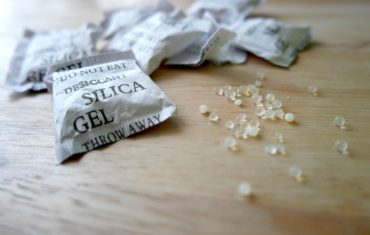

Over the last couple of decades or so, desiccant canisters have quickly evolved to become one of the pharmaceutical industry’s most important constituents. If you aren’t familiar with the term “desiccant canisters”, these are small HDPE (High Density Polyethylene) containers with adsorbents such as aluminum oxide, molecular sieves, or silica gel.

Desiccant containers used in food and pharmaceutical products are specially designed to be used with standard insertion equipment, which makes it easy for manufacturers to include them in factory lines creating medicine or food containers and bottles. Moreover, desiccant canisters come in various sizes to cater to pharmaceutical bottles of various sizes.

Desiccant Capsules

Just like desiccant canisters, desiccant capsules are primarily used to protect gels, tablets and medicines from moisture contamination and maintain their purity, quality, and potency over time. These are available in a diverse array of sizes and shapes, and can be specifically designed to fit requirements.

The Important Role Desiccant Canisters Play in the Pharmaceutical Industry

When it comes to the pharmaceutical sector, desiccant canisters play a critical role – with silica gel canisters being particularly popular. Most nutraceutical and pharmaceutical companies generally use desiccant canisters in the packaging of dental, diagnostic, herbal, dental, herbal, nutritional and veterinary. When these products are being packaged in bottles or containers, desiccant canisters are inserted to ensure that they aren’t impacted by moisture, mildew or micro-organisms.

When it comes to pharmaceutical and nutraceutical products, moisture control is essential. We’ve already mentioned that the presence of moisture can have an adverse effect on the quality and efficacy of the medicine. However, in some instances, moisture can also cause irreversible chemical and physical changes – potentially converting medicines into poison.

This is why an increasing number of pharma companies use desiccant canisters to ensure their products are protected from excess moisture and humidity.

A premier manufacturer and supplier of industrial-grade absorbents and desiccants, Sorbead India offers high-quality activated alumina, molecular sieves and other dehumidifiers for sale online. Get in touch with us to learn more about the products we offer.